Hilti HIT-HY 200: A Comprehensive Overview

Hilti HIT-HY 200, alongside HIT-V rods, offers robust anchoring solutions detailed in its Product Data Sheet, benefiting from injection mortar systems and basic loading data․

Hilti HIT-HY 200 represents a cutting-edge adhesive anchor system designed for reliable performance in diverse construction applications․ This system, comprehensively documented in the February 2013 and updated Jan-23 Product Data Sheet, combines a specialized injection mortar with compatible HIT-V anchor rods – including Zinc, Galvanized, A4-70, and HCR variants․

The system’s core strength lies in its ability to deliver enhanced bond strength, even in challenging conditions․ It addresses common issues like inadequately cleaned anchor holes, a frequent cause of performance reduction in conventional systems․ Furthermore, the HIT-HY 200 system is fully integrated with PROFIS anchor design software, enabling precise calculations and ensuring structural integrity․

Hilti Corporation and its Product Range

Hilti Corporation, known as Hilti AG or the Hilti Group, is a globally recognized manufacturer of high-quality construction tools, software, and fastening systems․ Their extensive product range encompasses power tools, networking and cordless systems, and, crucially, advanced adhesive anchors like the HIT-HY 200․

Hilti distinguishes itself through direct customer relationships and a commitment to innovation, employing approximately 34,000 people worldwide․ The HIT-HY 200 system exemplifies this dedication, supported by detailed Product Data Sheets and specialist support for on-site system design and implementation, ensuring optimal performance and safety․

Technical Specifications of HIT-HY 200

HIT-HY 200’s technical data, updated in January 2023, details application temperatures and performance characteristics, as found within the comprehensive product datasheet․

Chemical Composition and Properties

Hilti HIT-HY 200 is a two-part adhesive anchor system, comprising a vinyl polyester resin and a hardener․ This formulation delivers exceptional bond strength to various base materials, including concrete and masonry․ The product datasheet specifies its composition ensures reliable performance across diverse construction applications․

Key properties include high chemical resistance, low shrinkage during curing, and excellent flowability for complete adhesion within the drilled hole․ The system’s formulation minimizes water absorption, enhancing long-term durability․ It’s designed for both cracked and uncracked concrete, offering versatile anchoring solutions․

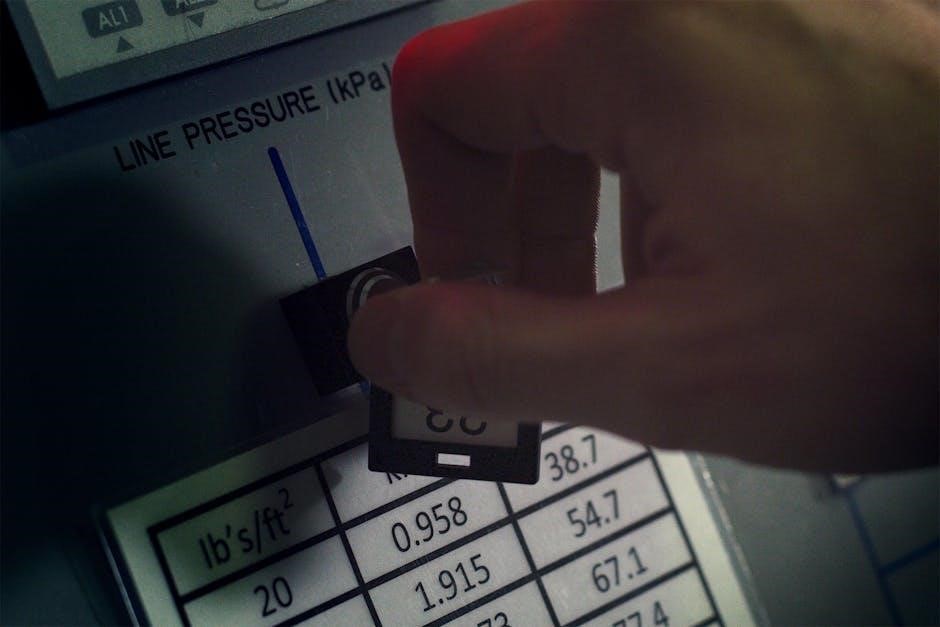

Application Temperature Range

Hilti HIT-HY 200’s application temperature range, as detailed in the product datasheet, is crucial for optimal performance․ Generally, application is permitted between +4°C and +40°C (39°F and 104°F) for both the adhesive and the base material․

However, specific conditions apply; base material temperatures should ideally be within this range․ Lower temperatures may extend curing times, while exceeding the upper limit can accelerate curing, potentially impacting bond strength․ Careful consideration of ambient and substrate temperatures is vital for successful installation, ensuring reliable anchoring․

Curing Time and Performance Characteristics

HIT-HY 200’s curing time varies based on temperature, with full performance achieved after 24 hours at 20°C (68°F)․ The product datasheet outlines load capacity based on curing duration․ Initial set occurs earlier, but full bond strength develops over time․

Performance characteristics are exceptional, offering high bond strength in both cracked and uncracked concrete․ Data sheets provide detailed load values for various anchor sizes (M8-M24) and installation depths․ Adhering to specified curing times is critical to realizing the system’s full load-bearing capabilities․

Key Features and Benefits

HIT-HY 200 boasts Hilti Safe-Set Technology, dust-free hole cleaning, and enhanced bond strength, as detailed in the product data sheet for optimal performance․

Hilti Safe-Set Technology

Hilti’s Safe-Set Technology, integral to the HIT-HY 200 system, significantly reduces the risk of performance issues stemming from inadequate hole cleaning․ Traditional adhesive anchors are highly susceptible to compromised performance when dust or debris remain within the drilled cavity․

This innovative technology minimizes the impact of imperfect cleaning, providing reliable anchoring even in less-than-ideal conditions․ The product data sheet highlights how Safe-Set ensures consistent bond strength, offering peace of mind and reducing the potential for costly failures․ It’s a key differentiator for this system․

Dust-Free Hole Cleaning

The Hilti HIT-HY 200 system addresses a common challenge: the dusty blowback experienced during traditional concrete hole cleaning with compressed air․ This system minimizes that issue, offering a cleaner and more efficient process․ While complete dust removal is always recommended, the HIT-HY 200 demonstrates enhanced performance even with minor residual dust․

The product data sheet doesn’t explicitly detail a “dust-free” method, but emphasizes the Safe-Set Technology’s ability to mitigate the negative effects of imperfect cleaning, improving overall reliability and reducing potential anchor failures․

Enhanced Bond Strength

The Hilti HIT-HY 200 adhesive anchor system delivers significantly enhanced bond strength, crucial for reliable performance in demanding applications․ The Product Data Sheet details basic loading data for single anchors ranging from M8 to M24, showcasing substantial load-bearing capabilities in both cracked and uncracked concrete․

This strength is achieved through the chemical composition and properties of the adhesive, coupled with the compatibility of HIT-V series anchor rods․ Proper installation, adhering to guidelines within the datasheet, is vital to realizing the system’s full potential․

Applications of HIT-HY 200

HIT-HY 200 excels in concrete and masonry anchoring, post-installed rebar connections, and structural strengthening, as outlined in the product data sheet․

Concrete and Masonry Anchoring

Hilti HIT-HY 200 provides a reliable solution for anchoring into concrete and masonry, detailed within its comprehensive technical data sheet․ This system eliminates risks associated with inadequately cleaned anchor holes, a common issue reducing performance in conventional systems․

The adhesive anchor system, when paired with HIT-V rods (Zinc, Galvanized, A4-70, or HCR), delivers exceptional holding power․ Proper installation, guided by the data sheet, ensures optimal load transfer and long-term durability in various construction applications․ It’s a versatile choice for securing fixtures and structural elements․

Post-Installed Rebar Connection

Hilti HIT-HY 200 excels in post-installed rebar connections, offering a robust alternative to traditional methods, as outlined in the product’s technical data sheet․ This system ensures structural integrity by creating a strong bond between existing concrete and new reinforcing steel․

Utilizing HIT-V rebar, the adhesive anchor provides exceptional pull-out resistance and load-bearing capacity․ The data sheet details specific loading data for various rebar diameters (M8-M24), crucial for accurate engineering calculations and safe, reliable connections in concrete structures․

Structural Strengthening

Hilti HIT-HY 200 provides a reliable solution for structural strengthening projects, detailed within its comprehensive technical data sheet․ This system effectively enhances load-bearing capacity and extends the service life of existing concrete structures․ By utilizing adhesive anchoring, it allows for the secure attachment of steel plates or sections to reinforce weakened areas․

The data sheet outlines performance data in both cracked and uncracked concrete, vital for accurate design calculations․ Compatibility with HIT-V series anchor rods ensures a strong, durable connection, meeting relevant standards and approvals for structural applications․

Installation Guidelines

HIT-HY 200 installation requires meticulous hole cleaning procedures, proper cartridge application, and compatibility with HIT-V anchor rods, as detailed in the data sheet․

Hole Cleaning Procedures

Hilti HIT-HY 200’s performance hinges on immaculate hole cleaning․ The Product Data Sheet emphasizes removing dust and debris before injection․ Compressed air, utilizing the Hilti nozzle, is recommended for efficient dust expulsion, preventing adhesion issues․

Multiple bursts are crucial, ensuring complete removal from the hole’s depth․ Brushing isn’t sufficient; it redistributes particles․ Proper cleaning eliminates inadequately-cleaned anchor holes, maximizing the adhesive anchor system’s strength․ Following these steps guarantees optimal bond strength and long-term reliability, as outlined in the technical documentation․

Cartridge Application and Usage

Hilti HIT-HY 200 cartridges require specific application techniques, detailed in the Product Data Sheet․ Use a compatible Hilti applicator gun for controlled dispensing․ Ensure the cartridge is properly seated and the nozzle is securely attached to prevent leakage․

Apply the adhesive slowly and consistently, starting from the back of the hole, avoiding air pockets․ The mortar should fill the entire annular space․ Discard the first few centimeters dispensed, as per instructions․ Adhere to the specified application temperature range for optimal curing, as outlined in the documentation․

Anchor Rod Compatibility (HIT-V Series)

Hilti HIT-HY 200 demonstrates optimal performance when paired with the HIT-V series anchor rods, as detailed in the Product Data Sheet․ Compatible options include HIT-V (Zinc), HIT-V-F (Galvanized), HIT-V-R (A4-70 stainless steel), and HIT-V-HCR rods․

Selecting the correct rod material is crucial based on the environmental conditions and load requirements․ The data sheet provides specific guidance on compatible diameters (M8-M24) and embedment depths for each rod type, ensuring a secure and reliable connection․ Always verify compatibility before installation․

Product Data Sheet Details (February 2013 & Jan-23 Updates)

HIT-HY 200’s data sheet (Feb ’13 & Jan ’23) outlines basic loading data for single anchors (M8-M24), performance in concrete, and relevant standards․

Basic Loading Data for Single Anchors (M8-M24)

Hilti HIT-HY 200’s product data sheet meticulously details basic loading data crucial for single anchor applications, covering a range of anchor sizes from M8 to M24․ This information is fundamental for engineers and installers to accurately assess load capacities․

The sheet provides characteristic load values for tension and shear, considering various embedment depths and concrete conditions․ These values are essential for safe and reliable anchor design, ensuring structural integrity․ The data is presented clearly, facilitating easy reference and application in project specifications․

Furthermore, the document specifies performance characteristics under both static and quasi-static loading scenarios, aiding in comprehensive load calculations․ It’s a vital resource for optimizing anchor selection and ensuring compliance with relevant building codes․

Performance Data in Cracked and Uncracked Concrete

Hilti HIT-HY 200’s technical data sheet provides comprehensive performance data for both cracked and uncracked concrete applications, a critical distinction for structural engineers․ The sheet details load capacities, considering the reduced strength in cracked concrete environments․

Characteristic values for tension and shear are presented separately for each condition, allowing for precise design calculations․ This data is essential for ensuring the long-term reliability and safety of anchored connections․ The documentation clearly outlines the testing methodologies used to determine these values․

Understanding these differences is paramount for selecting appropriate anchor sizes and embedment depths, guaranteeing structural integrity and adherence to building regulations․

Relevant Standards and Approvals

Hilti HIT-HY 200’s technical data sheet meticulously lists the relevant standards and approvals that validate its performance and safety․ These include European Technical Assessments (ETAs) and compliance with international building codes, ensuring widespread applicability․

The documentation confirms adherence to rigorous testing protocols, demonstrating the system’s reliability in diverse construction scenarios․ Approvals from recognized certification bodies provide assurance to engineers and contractors․

This adherence to standards is crucial for project compliance and obtaining necessary building permits, solidifying HIT-HY 200 as a trusted anchoring solution․

PROFIS Anchor Design Software Integration

HIT-HY 200 calculations are seamlessly integrated into PROFIS anchor design software, facilitating precise and safe anchor design based on technical data․

Using PROFIS for HIT-HY 200 Calculations

Hilti’s PROFIS anchor design software streamlines calculations for the HIT-HY 200 adhesive anchor system․ Utilizing data from the Product Data Sheet, PROFIS enables engineers to accurately determine load capacities, considering factors like concrete strength, anchor spacing, and edge distances․

The software facilitates design checks for both cracked and uncracked concrete, ensuring compliance with relevant standards․ Users can input specific project parameters and receive detailed reports, optimizing anchor selection and ensuring structural integrity․ PROFIS simplifies complex calculations, reducing design time and minimizing potential errors․

Design Considerations and Safety Factors

When employing HIT-HY 200, careful design consideration, guided by the Product Data Sheet, is crucial․ Factors like concrete condition (cracked or uncracked) significantly impact allowable loads․ Appropriate safety factors, as defined by relevant standards, must be applied to account for uncertainties in material properties and installation quality․

Anchor spacing, edge distances, and the type of HIT-V rod used (Zinc, Gal, A4-70, HCR) all influence performance․ Utilizing Hilti’s PROFIS software aids in accurately determining these factors, ensuring a safe and reliable anchoring solution that meets project requirements․

Safety Precautions and Handling

HIT-HY 200 requires Personal Protective Equipment (PPE) during handling, as outlined in the data sheet, and proper storage to maintain shelf life․

Personal Protective Equipment (PPE)

When utilizing the Hilti HIT-HY 200 system, adherence to stringent safety protocols is paramount․ The product data sheet explicitly mandates the use of appropriate Personal Protective Equipment (PPE) to safeguard personnel․ This includes, but isn’t limited to, chemical-resistant gloves to prevent skin contact with the adhesive․

Safety glasses or a face shield are crucial to protect eyes from potential splashes․ Respiratory protection, such as a respirator, is recommended in poorly ventilated areas to avoid inhaling vapors․

Appropriate work clothing, covering arms and legs, should also be worn․ Always consult the full product data sheet for a comprehensive list and specific recommendations regarding PPE․

Storage and Shelf Life

Proper storage is critical to maintain the Hilti HIT-HY 200’s performance and ensure its longevity․ The product data sheet details specific storage requirements, emphasizing the need to keep cartridges in a cool, dry environment, protected from direct sunlight and freezing temperatures․

Unopened cartridges generally have a shelf life of approximately 18 months from the date of manufacture, clearly marked on the packaging․

Once opened, the cartridge should be used within a reasonable timeframe, as exposure to air can initiate curing․ Always verify the expiration date before use and discard any expired product․

Recent Developments & UTECH News (November 26, 2025)

Hilti Group’s Russian subsidiary was acquired by local management on November 26, 2025, following regulatory approval, focusing on innovation and sustainability․

Hilti Group’s Russian Subsidiary Acquisition

On November 26, 2025, a significant development unfolded as Hilti Group’s Russian subsidiary transitioned to local management ownership․ This strategic move followed a thorough review and subsequent approval by the relevant regulatory bodies․ The acquisition signifies a restructuring of Hilti’s operations within Russia, adapting to the evolving geopolitical landscape․

This decision allows for continued service to customers in the region, albeit under new leadership․ Hilti maintains its commitment to innovation, quality, and direct customer relationships globally, while navigating the complexities of the Russian market through this localized structure․ The company continues to operate with approximately 34,000 employees worldwide․

Innovation and Sustainability Focus

Hilti consistently prioritizes innovation, delivering cutting-edge solutions like the HIT-HY 200 adhesive anchor system․ This commitment extends to sustainability, aiming to enhance productivity, safety, and ecological responsibility in construction․ The company develops electro-tools, fastening systems, and building software with these principles at their core․

Hilti’s dedication to sustainable practices influences product design and operational processes․ They strive to minimize environmental impact while maximizing performance and durability․ This focus ensures long-term value for customers and a responsible approach to the construction industry’s future․

Comparison with Other Hilti Adhesive Anchors

HIT-HY 200 distinguishes itself from HIT-RE 500 through specific performance characteristics and application suitability, as detailed within respective product data sheets․

HIT-HY 200 vs․ HIT-RE 500

HIT-HY 200 and HIT-RE 500 represent Hilti’s advanced adhesive anchor systems, each tailored for distinct project demands․ Examining their respective product data sheets reveals key differences․ HIT-HY 200 excels in applications requiring dust-free hole cleaning and enhanced bond strength, particularly with its Safe-Set Technology․

Conversely, HIT-RE 500 often suits higher load-bearing requirements and challenging environmental conditions․ The choice hinges on specific load calculations, concrete conditions (cracked vs․ uncracked), and the anchor rod compatibility – HIT-V series being crucial for both․ Careful consideration of these factors, guided by PROFIS anchor design software, ensures optimal performance and safety․

Choosing the Right Adhesive Anchor for Your Project

Selecting the ideal Hilti adhesive anchor demands a thorough project assessment․ Begin by consulting the relevant Product Data Sheet for HIT-HY 200, considering concrete type, load requirements, and environmental factors․ Utilize PROFIS anchor design software for precise calculations, factoring in cracked or uncracked concrete conditions․

HIT-HY 200’s dust-free cleaning and Safe-Set Technology are advantageous in many scenarios․ However, for exceptionally high loads or specific approvals, HIT-RE 500 might be more suitable․ Always prioritize compatibility with HIT-V anchor rods and adhere to specified installation guidelines for optimal performance․

Availability and Purchasing Information

HIT-HY 200 is readily available through authorized Hilti dealers, offering competitive pricing and specific product codes detailed in the official catalog․

Authorized Hilti Dealers

Hilti maintains a comprehensive network of authorized dealers globally, ensuring customers have convenient access to HIT-HY 200 and related products․ These dealers provide expert advice, technical support, and local inventory․

Locating a dealer is simple through the official Hilti website, utilizing their dealer locator tool․ Dealers often offer specialized services, including on-site consultations and training, assisting with project-specific anchoring requirements․ They can furnish the latest Product Data Sheets, including the February 2013 and Jan-23 updates, and guide selection based on application needs․ Purchasing through authorized channels guarantees genuine Hilti quality and warranty support․

Pricing and Product Codes

HIT-HY 200 pricing varies based on cartridge size, quantity purchased, and dealer location․ Obtaining a precise quote requires contacting an authorized Hilti dealer directly․ Product codes are essential for accurate ordering and referencing the relevant Product Data Sheet (February 2013 & Jan-23 updates);

Typical codes differentiate between cartridge volumes and accompanying HIT-V rod bundles․ Dealers can provide a complete price list and assist in identifying the correct codes for specific anchor sizes (M8-M24) and project demands․ Remember to specify the desired quantity for potential bulk discounts․