Music theory unveils the elements – rhythm‚ melody‚ and harmony – acting as the foundational “secret sauce” for every musical creation‚ enhancing musicianship.

What is Music Theory?

Music theory isn’t a rigid set of rules‚ but rather a framework for understanding how music works. It’s the study of the practices and possibilities of music‚ delving into the elements that comprise a composition. This includes examining rhythm‚ melody‚ harmony‚ and the underlying structures that give music its form and emotional impact.

Essentially‚ it’s a language – a system of symbols and concepts – that allows musicians to communicate and analyze music effectively. Understanding this language empowers you to not only appreciate music on a deeper level‚ but also to create your own‚ informed by a knowledge of established principles. It’s about recognizing patterns and relationships within sound.

Why Learn Music Theory?

Learning music theory significantly enhances your overall musicianship‚ regardless of your instrument or preferred genre. It provides a deeper understanding of the music you play‚ write‚ or listen to‚ moving beyond simply recognizing sounds to comprehending why those sounds evoke certain feelings.

For songwriters‚ it unlocks creative potential‚ enabling more informed harmonic choices and melodic development. Guitarists‚ pianists‚ and producers benefit from a stronger grasp of chord progressions and arrangement techniques. Ultimately‚ music theory empowers you to become a more versatile and expressive musician‚ fostering a richer connection with the art form and improving your ability to communicate musically.

The Building Blocks: Notes and the Staff

Notes (A‚ B‚ C‚ D‚ E‚ F‚ G) are the fundamental units of music‚ visually represented on the musical staff with varying clefs for pitch indication.

Understanding Notes (A‚ B‚ C‚ D‚ E‚ F‚ G)

Notes represent musical sounds‚ forming the basic vocabulary of music. The seven natural notes – A‚ B‚ C‚ D‚ E‚ F‚ and G – cycle repeatedly to create melodies and harmonies. Understanding their relationships is crucial. These notes can be altered using sharps (#)‚ which raise a note by a half step‚ and flats (♭)‚ which lower a note by a half step.

The placement of a note on the staff determines its pitch. Notes are named relative to their position on the staff‚ and learning to quickly identify them is a foundational skill. Recognizing these notes isn’t just about memorization; it’s about developing an intuitive understanding of musical intervals and relationships‚ ultimately aiding in ear training and composition.

The Musical Staff and Clefs

The musical staff‚ comprised of five horizontal lines and four spaces‚ provides the framework for notating music. Notes are placed on these lines and spaces to indicate their pitch. Clefs are essential symbols that define the pitch of the notes on the staff. The most common clefs are the treble clef (G clef)‚ used for higher-pitched instruments and voices‚ and the bass clef (F clef)‚ used for lower-pitched instruments.

Understanding clefs is vital for accurately reading music. The clef tells you which line or space represents a specific note‚ like middle C. Different clefs are used for different instruments to avoid excessive ledger lines. Mastering the staff and clefs unlocks the ability to decipher written music and translate it into sound.

Rhythm and Time

Rhythm governs music’s timing‚ encompassing beat‚ tempo‚ and meter. Note values – whole‚ half‚ quarter‚ and eighth – define durations within a musical measure.

Beat‚ Tempo‚ and Meter

Understanding beat‚ tempo‚ and meter is crucial for grasping musical time. The beat is the basic unit of time‚ the pulse you tap your foot to; Tempo dictates the speed of that beat‚ often measured in beats per minute (BPM) – allegro for fast‚ adagio for slow‚ for example.

Meter organizes beats into recurring patterns‚ or measures. These patterns are indicated by a time signature‚ like 4/4 (common time)‚ meaning four beats per measure‚ with the quarter note receiving one beat. Other common meters include 3/4 (waltz time) and 6/8. Recognizing these elements allows musicians to accurately perform and interpret rhythmic structures‚ forming the backbone of any musical piece.

Note Values (Whole‚ Half‚ Quarter‚ Eighth)

Note values determine the duration of a sound. A whole note receives four beats in 4/4 time‚ serving as the longest standard note value. A half note is worth two beats‚ visually represented as an open note with a stem. The quarter note gets one beat‚ and is often considered the basic unit for counting time.

Further dividing the beat‚ an eighth note receives half a beat. Each subsequent division (sixteenth‚ thirty-second notes‚ etc.) halves the duration. These values are not absolute; they are relative to the tempo and time signature. Understanding these relationships is fundamental for accurately reading and performing rhythms‚ allowing musicians to control the flow of time within a piece.

Intervals: The Distance Between Notes

Intervals define the distance between two notes‚ each possessing a unique sound and mood; recognizing them by ear aids in melody comprehension.

Defining Intervals (Major‚ Minor‚ Perfect)

Intervals are categorized as major‚ minor‚ or perfect‚ defining their specific qualities. A perfect interval‚ like a perfect fourth or fifth‚ sounds stable and consonant. Major intervals possess a brighter‚ more expansive quality‚ while minor intervals evoke a darker‚ more melancholic feel.

Understanding these distinctions is crucial for analyzing and composing music. The quality of an interval significantly impacts the emotional character of a melody or chord progression. For instance‚ a major third often sounds cheerful‚ whereas a minor third can sound sad. Recognizing these qualities allows musicians to intentionally craft specific moods and expressions within their music. The theory behind intervals requires knowledge of scales and keys‚ as the context determines the interval’s classification.

Recognizing Intervals by Ear

Ear training is paramount for musicians; mastering interval recognition is a key component. Each interval possesses a unique sonic fingerprint‚ and consistent practice allows you to identify them instantly. Melodies are fundamentally sequences of intervals‚ so discerning these distances unlocks melodic comprehension.

If you train your ear to recognize intervals‚ you can figure out melodies by ear! Start with simple intervals like perfect fifths and octaves‚ then progress to more complex ones. Utilize online resources or apps designed for ear training. Consistent practice‚ even for short periods‚ yields significant improvements. This skill enhances improvisation‚ transcription‚ and overall musical intuition‚ allowing for deeper engagement with music.

Scales and Keys

Scales and keys‚ though potentially tricky for beginners‚ are vital concepts worth mastering; they underpin harmonic structure and melodic possibilities in music.

Major Scales: Construction and Characteristics

Major scales form the bedrock of much Western music‚ possessing a bright and cheerful quality. Their construction follows a specific pattern of whole and half steps: Whole-Whole-Half-Whole-Whole-Whole-Half. Starting on any note‚ applying this formula creates a major scale.

For example‚ the C major scale (C-D-E-F-G-A-B-C) contains no sharps or flats. Each major scale has a unique characteristic sound due to the intervals between its notes. Understanding these intervals is crucial for recognizing and constructing melodies and harmonies. The consistent pattern provides a predictable‚ yet versatile‚ framework for musical expression‚ making them essential for any aspiring musician to learn.

Minor Scales: Types and Usage

Minor scales evoke a range of emotions‚ often described as sad‚ melancholic‚ or dramatic‚ contrasting with the brighter character of major scales. Unlike major scales‚ minor scales come in several forms: natural‚ harmonic‚ and melodic. The natural minor scale maintains a consistent whole and half-step pattern‚ while the harmonic minor raises the seventh degree‚ creating a stronger pull towards the tonic.

The melodic minor raises both the sixth and seventh degrees ascending‚ but reverts to the natural minor descending. These variations offer distinct harmonic possibilities. Composers utilize minor scales to express a wider emotional palette‚ and understanding their nuances is vital for interpreting and creating music with depth and feeling.

Key Signatures

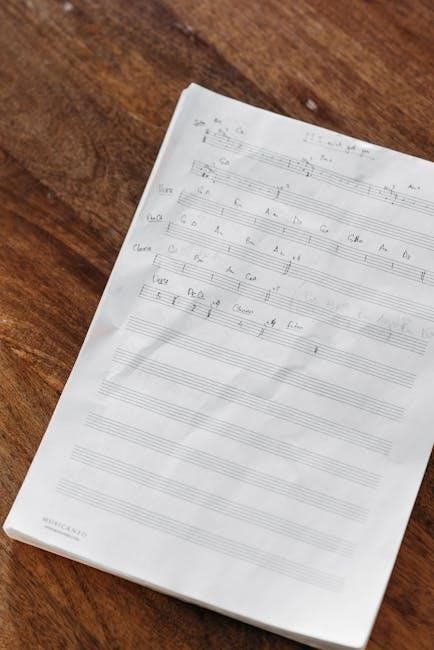

Key signatures‚ displayed at the beginning of sheet music‚ indicate sharps or flats‚ defining the scale and key of a musical piece efficiently.

Sharps and Flats

Sharps (#) and flats (♭) are musical symbols that alter the pitch of a note. A sharp raises a note by a half step‚ while a flat lowers it by a half step. These alterations are crucial for defining keys and creating harmonic interest within a composition.

The number of sharps or flats in a key signature directly corresponds to the key’s tonal center. Understanding how sharps and flats function is essential for reading music and comprehending the relationships between notes within a scale. They aren’t arbitrary; they systematically define the key’s character.

For instance‚ a key signature with one sharp indicates the G major key (or E minor)‚ while a key signature with one flat signifies the F major key (or D minor). Mastering sharps and flats unlocks a deeper understanding of musical structure and harmonic possibilities.

Determining Key Signatures

Key signatures‚ displayed at the beginning of sheet music‚ reveal the sharps or flats present in a particular key. Deciphering these signatures is fundamental to understanding the tonal context of a piece. A systematic approach simplifies this process.

For sharps‚ the key can be found using the formula: note one half-step above the last sharp. Conversely‚ for flats‚ the key is the second-to-last flat. Memorizing the order of sharps (F#‚ C#‚ G#‚ D#‚ A#‚ E#‚ B#) and flats (Bb‚ Eb‚ Ab‚ Db‚ Gb‚ Cb‚ Fb) is incredibly helpful.

Practice identifying key signatures regularly to build fluency. Recognizing these patterns allows musicians to quickly grasp the harmonic landscape and anticipate the notes within a composition‚ enhancing both performance and comprehension.

Chords: Harmony in Action

Chords‚ built from triads – major‚ minor‚ diminished‚ and augmented – create harmonic depth. Understanding basic chord progressions unlocks the principles of musical harmony.

Triads (Major‚ Minor‚ Diminished‚ Augmented)

Triads are the fundamental building blocks of chords‚ formed by stacking three notes on top of each other. The quality of a triad – whether it’s major‚ minor‚ diminished‚ or augmented – is determined by the intervals between these notes. A major triad has a bright‚ happy sound‚ constructed with a root‚ a major third‚ and a perfect fifth. Conversely‚ a minor triad evokes a more somber mood‚ utilizing a root‚ a minor third‚ and a perfect fifth.

Diminished triads create tension and instability‚ built with a root‚ a minor third‚ and a diminished fifth. Augmented triads‚ with a root‚ a major third‚ and an augmented fifth‚ possess a surreal and unresolved quality. Recognizing these qualities is crucial for understanding the emotional impact of different chords and progressions‚ allowing musicians to craft compelling harmonic landscapes.

Chord Progressions: Basic Principles

Chord progressions are the sequence of chords played one after another‚ forming the harmonic foundation of a song. They create a sense of movement and direction‚ guiding the listener’s ear. Common progressions often revolve around the tonic (I)‚ subdominant (IV)‚ and dominant (V) chords within a key. The dominant chord‚ particularly‚ creates a strong pull back to the tonic‚ establishing a sense of resolution.

Understanding these basic principles allows musicians to predict chord changes and create satisfying harmonic structures. Progressions can be simple or complex‚ utilizing inversions‚ substitutions‚ and passing chords to add color and interest. Effective progressions build tension and release‚ contributing significantly to the emotional impact of a musical piece.

Melody and Harmony

Melodies‚ sequences of intervals‚ interact with harmony – the chords supporting them – to create musical depth and emotional resonance‚ enriching the overall sound.

Creating Melodies

Crafting compelling melodies involves understanding how intervals – the distances between notes – contribute to a song’s character. Each interval possesses a unique sonic quality and evokes distinct moods. A strong melody isn’t simply a random sequence of notes; it’s a carefully constructed phrase that balances predictability and surprise.

Begin by experimenting with different scale degrees within a chosen key. Consider the contour of the melody – does it ascend‚ descend‚ or remain relatively static? Utilize rhythmic variation to add interest and prevent monotony. Think about phrasing; melodies often unfold in balanced segments‚ much like sentences in language.

Developing your ear is crucial. Try to “sing” melodies before writing them down‚ and analyze existing melodies to identify the techniques composers employ. Remember‚ a memorable melody is often singable and emotionally resonant‚ connecting with listeners on a deeper level.

How Melody and Harmony Interact

Melody and harmony aren’t isolated elements; they exist in a symbiotic relationship‚ each enhancing the other. Harmony provides the supportive backdrop for the melody‚ adding depth‚ color‚ and emotional context. Chords‚ the building blocks of harmony‚ can reinforce the melodic contour or create tension and release.

Consider how different chord progressions can alter the perceived mood of a melody. A major chord progression generally evokes feelings of happiness or triumph‚ while a minor progression often suggests sadness or introspection. Dissonance‚ created by certain harmonic clashes‚ can add drama and complexity.

Effective interplay requires careful voice leading – ensuring smooth transitions between chords and avoiding awkward jumps. Ultimately‚ the goal is to create a cohesive sound where melody and harmony work together to tell a compelling musical story.

Musical Form

Musical form defines a piece’s structure‚ utilizing common patterns like verse-chorus or AABA‚ providing a recognizable framework for listeners and composers.

Common Forms (Verse-Chorus‚ AABA)

Verse-chorus form is incredibly prevalent in popular music‚ offering a dynamic contrast. Verses typically develop the narrative or explore different musical ideas‚ while the chorus provides a memorable‚ repeating section – often the song’s emotional core. This structure creates familiarity and engagement.

AABA form‚ common in older popular songs and jazz standards‚ presents a different approach. Two similar ‘A’ sections establish a melodic idea‚ followed by a contrasting ‘B’ section (the bridge)‚ which introduces harmonic or melodic variation. The return of the ‘A’ section provides resolution.

Understanding these forms isn’t just about labeling songs; it’s about recognizing how composers use structure to create emotional impact and guide the listener’s experience. Recognizing these patterns enhances both listening and compositional skills.

Understanding Musical Structure

Musical structure refers to the overall organization of a composition‚ encompassing how different sections are arranged and relate to each other. It’s more than just form (like verse-chorus); it’s about the flow of musical ideas and how they build tension and release.

Elements like repetition‚ contrast‚ and variation are crucial. Repetition creates familiarity‚ contrast introduces interest‚ and variation keeps the music engaging. These elements work together to create a cohesive and satisfying listening experience.

Analyzing structure involves identifying sections‚ recognizing patterns‚ and understanding how the composer uses these techniques to achieve a specific artistic effect. This skill is vital for both performers and composers‚ allowing for informed interpretation and effective creation.

Advanced Concepts (Brief Overview)

Modes and seventh chords expand harmonic possibilities‚ offering nuanced colors beyond basic scales and triads‚ enriching compositions with complexity and depth.

Modes

Modes represent variations of a scale‚ each possessing a distinct character and melodic flavor. Derived from the major scale (Ionian)‚ they offer alternative tonal palettes for composers and improvisers. Think of them as different “moods” built from the same notes‚ but starting on a different degree.

There are seven primary modes: Ionian‚ Dorian‚ Phrygian‚ Lydian‚ Mixolydian‚ Aeolian‚ and Locrian. Each mode creates a unique sound due to the specific intervals present within it. For example‚ Dorian has a minor quality with a characteristic raised sixth‚ while Lydian boasts a bright‚ ethereal sound thanks to its raised fourth.

Understanding modes allows musicians to move beyond traditional major and minor tonalities‚ adding depth and sophistication to their musical expression. Exploring modes unlocks a wider range of melodic and harmonic possibilities‚ fostering creativity and individuality.

Seventh Chords

Seventh chords add a fourth note to a triad‚ creating a richer‚ more complex harmonic texture. This additional note‚ a seventh interval above the root‚ introduces tension and color‚ moving beyond the simplicity of basic triads. They are fundamental to jazz‚ blues‚ and many other genres‚ providing harmonic depth and sophistication.

The most common types include major seventh‚ minor seventh‚ dominant seventh‚ half-diminished seventh‚ and fully diminished seventh chords. Each type possesses a unique sonic quality determined by the intervals present. Dominant seventh chords‚ for instance‚ create a strong pull towards resolution‚ while minor seventh chords evoke a melancholic mood.

Mastering seventh chords expands harmonic vocabulary‚ enabling musicians to create more nuanced and expressive compositions and improvisations. They are essential for understanding advanced harmonic concepts and adding depth to musical arrangements.