Door Closer Adjustment Instructions: A Comprehensive Guide

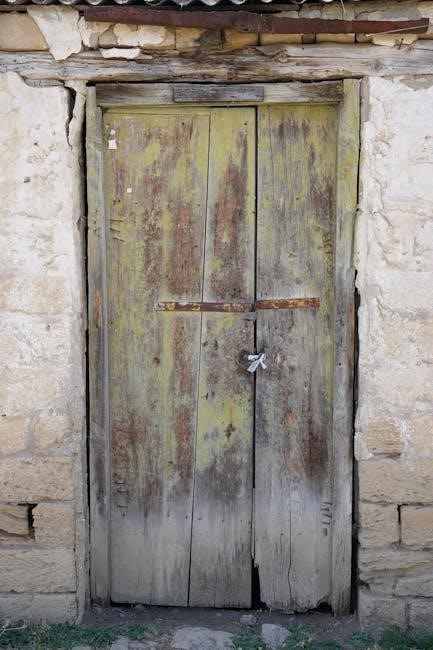

Maintaining optimal door function requires periodic adjustments to your door closer. This guide provides detailed steps for smooth and secure operation, ensuring longevity.

Understanding Door Closers

Door closers are mechanical devices designed to automatically close a door after it has been opened. They play a crucial role in building security, accessibility, and energy conservation by ensuring doors are reliably shut.

These devices utilize a spring mechanism, often hydraulic or pneumatic, to control the door’s closing speed and force. Understanding the core components – the body, the spring, and the fluid-filled cylinder – is key to effective adjustment. Different closers cater to varying door weights and traffic levels.

Properly functioning door closers enhance fire safety by containing smoke and flames, and they also contribute to noise reduction. Familiarizing yourself with their basic principles will empower you to diagnose and resolve common operational issues efficiently.

Types of Door Closers

Door closers aren’t one-size-fits-all; they come in several types, each suited for specific applications and aesthetic preferences. The most common are surface mounted closers, installed directly onto the door and frame, offering easy installation and adjustment.

Concealed closers are hidden within the door itself, providing a sleek, minimalist appearance, ideal for modern designs. These require more complex installation. Floor closers, as the name suggests, are mounted into the floor, suitable for high-traffic areas and doors that swing in both directions.

Choosing the right type depends on factors like door weight, frequency of use, and desired aesthetics. Understanding these differences is crucial before attempting any adjustments, as procedures vary between types.

Surface Mounted Closers

Surface mounted closers are the most prevalent type due to their straightforward installation and ease of adjustment. They are visibly attached to the door and frame using screws, making them accessible for maintenance. These closers typically feature two adjustment valves – one for closing speed and another for latching speed.

Adjustment is generally performed using a screwdriver, turning the valves to increase or decrease resistance. Identifying these valves is the first step in the adjustment process. They are usually clearly marked with symbols indicating their function.

Proper adjustment ensures the door closes smoothly and securely without slamming, contributing to safety and longevity. Regular checks and minor adjustments can prevent more significant issues down the line.

Concealed Closers

Concealed closers, also known as hidden or mortise closers, are installed within the door itself, offering a sleek and unobtrusive appearance. Adjustment of these closers often requires removal of a cover plate to access the internal mechanisms. They generally utilize a more complex adjustment system compared to surface mounted models.

Typically, concealed closers have adjustment screws or valves for controlling closing speed, latching speed, and sometimes backcheck intensity. Accessing these adjustments can be more challenging due to the concealed nature of the closer. Specialized tools may be needed.

Precise adjustment is crucial for optimal performance, as improper settings can lead to binding or inefficient operation. Consulting the manufacturer’s instructions is highly recommended for concealed closer adjustments.

Floor Closers

Floor closers are mounted into the floor, providing a discreet solution for doors needing a heavy-duty closing mechanism, often used for high-traffic or security applications. Adjustment typically involves accessing screws located on the closer’s body, often requiring a specialized Allen wrench or screwdriver.

These closers generally offer adjustments for closing speed, latching speed, and backcheck. Due to their robust construction and underground installation, floor closers can be more difficult to adjust than other types. Ensuring the door alignment is correct is paramount before adjustment.

Proper adjustment requires understanding the interplay between the closer’s settings and the door’s weight and swing. Always refer to the manufacturer’s specific instructions for your floor closer model.

Initial Inspection & Safety

Before adjusting, carefully inspect the door closer and surrounding area. Prioritize safety by wearing appropriate protection and understanding potential hazards.

Checking for Damage

A thorough inspection for damage is crucial before attempting any adjustments. Begin by visually examining the closer’s body for cracks, dents, or signs of corrosion. Pay close attention to the mounting points – are the screws secure, and is the mounting bracket itself undamaged?

Next, check the connecting linkages (arms) for bends, breaks, or loose connections. Ensure the spring mechanism appears intact and isn’t visibly compromised. Gently attempt to move the door; any unusual noises, like grinding or clicking, could indicate internal damage.

Finally, inspect the door itself and the frame for any signs of wear or damage that might be contributing to the issue. If significant damage is found, do not attempt to adjust the closer; professional repair or replacement is recommended.

Identifying Closer Type & Markings

Correct identification of your door closer type is essential for proper adjustment. Closers are broadly categorized as surface mounted, concealed, or floor-mounted – observe how it’s installed to determine the type.

Locate the manufacturer’s label, usually found on the closer’s body. This label contains vital information, including the model number and potentially a diagram illustrating adjustment points. Note the model number; this will be invaluable when searching for specific adjustment instructions online or contacting the manufacturer.

Many closers also have adjustment indicators – arrows or symbols near the adjustment valves. Familiarize yourself with these markings before proceeding. Understanding your closer’s specifics ensures you’re making the correct adjustments for optimal performance and avoids potential damage.

Safety Precautions Before Adjustment

Prioritize safety before attempting any door closer adjustments. Always inform building occupants that you will be working on the door to prevent accidental use during the process. Wear appropriate safety glasses to protect your eyes from potential spring tension release or debris.

Support the door during adjustments, especially when working with powerful closers. A door that suddenly swings shut due to incorrect adjustment can cause injury or damage. Never disassemble the closer completely unless you are a qualified technician.

Be mindful of pinch points and avoid placing hands or fingers near moving parts. If you encounter significant resistance or are unsure about any step, stop and consult a professional. Ignoring these precautions could lead to injury or damage to the door and closer.

Basic Adjustment Principles

Door closer adjustments primarily focus on controlling closing speed, latching speed, and backcheck intensity, ensuring controlled and safe door operation for all users.

Closing Speed Control

Closing speed is arguably the most frequently adjusted setting on a door closer. It dictates how quickly the door moves from approximately 70 degrees open to the latching point. A properly adjusted closing speed ensures the door doesn’t swing forcefully, preventing injury or damage, while still providing a secure closure.

Most door closers feature a valve, typically a screw, that controls this speed. Turning the valve in one direction will increase the speed, causing the door to close faster, while turning it in the opposite direction will decrease the speed, resulting in a slower, more controlled closure. It’s crucial to make small adjustments and observe the door’s movement after each change to achieve the desired effect. Consider the door’s usage and the building’s occupants when setting the closing speed.

Latching Speed Control

Latching speed governs the final few degrees of the door’s closing motion – the speed at which it draws firmly into the latch. This is separate from the overall closing speed and is vital for ensuring a positive latch, preventing the door from bouncing back open. A correctly adjusted latching speed provides a secure closure without creating excessive noise or wear on the door and frame.

Typically, latching speed is adjusted via a separate valve, often located near the closing speed control. Increasing the latching speed will cause the door to snap into the latch more forcefully, while decreasing it will result in a gentler, more controlled latch. Again, small adjustments are key. Too much latching speed can damage the door, while too little may result in an unreliable closure. Observe the latching action carefully after each adjustment.

Backcheck Intensity

Backcheck is a feature designed to prevent doors from being forced open rapidly, particularly in high-traffic or windy conditions. It creates resistance against the door as it approaches the fully open position, controlling the swing and protecting both the door and the surrounding structure. Adjusting the backcheck intensity allows you to tailor this resistance to the specific environment and door usage.

The backcheck adjustment is usually a valve or screw, often found on the closer body. Increasing the backcheck provides more resistance, slowing the door’s opening swing. Decreasing it reduces the resistance, allowing for easier opening. Start with a minimal adjustment and gradually increase until the desired level of control is achieved. Excessive backcheck can make the door difficult to open, so careful fine-tuning is essential for optimal performance and user convenience.

Adjusting Closing Speed

Controlling the door’s closing speed ensures a gentle, controlled motion, enhancing safety and preventing slamming. Adjustments are typically made via a regulating valve.

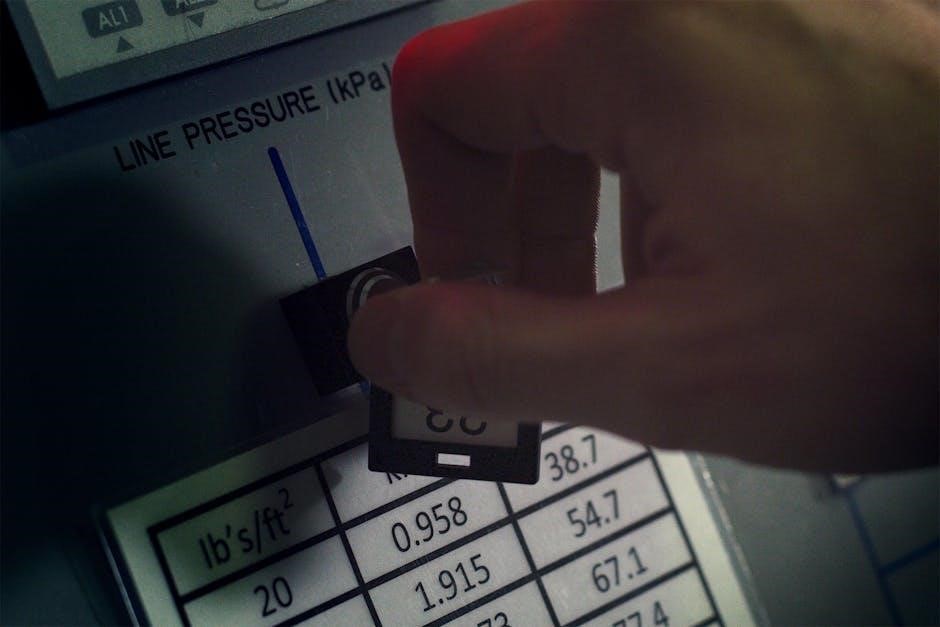

Locating the Closing Speed Adjustment Valve

Identifying the closing speed adjustment valve is the first step in modifying how quickly your door shuts. Typically, this valve is found on the body of the door closer itself, often near the cylinder. It usually appears as a small screw or dial, frequently marked with a “+” and “-” symbol, or labeled “Closing Speed.”

Look for two separate valves – one controls the overall closing speed, while the other manages the latching speed (we’ll cover that later!). The closing speed valve generally affects the majority of the door’s travel. Depending on the closer’s model, the valve might be recessed and require a small screwdriver to access. Consult your door closer’s manual if you’re having trouble locating it, as designs can vary between manufacturers.

Adjusting for Faster Closing

To increase the closing speed of your door, locate the closing speed adjustment valve (as described previously). Using a screwdriver (typically Phillips head, but check your model), turn the valve in the direction indicated for faster closing – usually marked with a “+” symbol or the word “Fast.”

Make small adjustments, a quarter-turn at a time, and test the door’s closing speed after each adjustment. Avoid turning the valve too far at once, as this can cause the door to slam shut. Observe the door’s movement throughout its entire arc, ensuring it closes consistently and doesn’t catch or bind. Remember to prioritize safety and controlled movement over simply maximizing speed.

Adjusting for Slower Closing

If your door is closing too quickly, or you need to reduce the closing speed for accessibility or noise reduction, you’ll adjust the closing speed valve in the opposite direction. Locate the valve – again, referencing the earlier section on identification – and turn it in the direction indicated for slower closing, typically marked with a “-” symbol or the word “Slow.”

Similar to speeding up the closing, make incremental adjustments of about a quarter-turn. Test the door’s closing speed after each adjustment to gauge the effect. Be patient; achieving the desired speed may require several small adjustments. Ensure the door closes fully and latches securely at the slower speed, avoiding any hesitation or sticking. Prioritize a smooth, controlled closure.

Adjusting Latching Speed

Controlling the final portion of the door’s movement, latching speed ensures a gentle, secure closure without slamming. Fine-tune this for optimal performance.

Finding the Latching Speed Adjustment Valve

Locating the latch speed valve is typically straightforward, though slight variations exist between door closer models. Generally, it’s a small valve, often labeled “LS” or with a symbol depicting a latch, situated near the closing speed adjustment.

Examine the closer body carefully; the latch valve is usually a separate, smaller screw or dial. On some models, it might be recessed and require a small screwdriver to access. Refer to your specific door closer’s manual if you’re having trouble identifying it – manufacturer diagrams are incredibly helpful.

Remember to avoid forcing anything; if resistance is met, double-check the manual or consult a professional. Incorrectly identifying the valve could lead to unintended adjustments to other settings.

Fine-Tuning Latching Speed

Once you’ve located the latch speed valve, make small adjustments – typically ¼ turn at a time – and test the door’s closing action. Increase the speed by turning the valve clockwise, decreasing it by turning counterclockwise. The goal is a firm, positive latch without slamming.

Observe how the door behaves in the final few inches of its travel. Too slow, and it might not latch reliably; too fast, and it will slam. Repeat the adjustment and testing process until you achieve a smooth, controlled latch.

Be patient; fine-tuning latch speed often requires several iterations. Consider the door’s weight and usage frequency when setting the speed – heavier doors or high-traffic areas may need a slightly faster latch.

Backcheck Adjustment

Backcheck controls door opening force near the end of the swing, preventing damage. Adjust it to resist forceful opening and protect walls and fixtures.

Understanding Backcheck Function

Backcheck is a crucial feature on many door closers designed to prevent doors from swinging open too forcefully, particularly in high-traffic or windy conditions. It works by increasing the resistance to door opening during the final 20-30 degrees of the swing. This controlled resistance prevents the door from slamming into walls, people, or furniture, minimizing damage and enhancing safety.

Essentially, backcheck acts as a hydraulic brake, absorbing the momentum of the door as it approaches its fully open position. It’s particularly useful for doors that are frequently pushed open quickly or are exposed to drafts. Properly adjusted backcheck doesn’t make the door difficult to open normally, but provides a noticeable resistance only near the end of its arc. Ignoring backcheck can lead to wear and tear on the door, frame, and the closer itself.

Adjusting Backcheck Intensity

Locate the backcheck adjustment valve – typically a small screw found on the closer body, often near the speed adjustment valves. Turning this valve clockwise increases backcheck intensity, providing greater resistance during the final portion of the door’s swing. Counter-clockwise rotation decreases the resistance.

Adjust in small increments – a quarter turn at a time – and test the door’s operation after each adjustment. Observe how much force is required to push the door open during the last few inches of its travel. The goal is to find a setting that prevents slamming without making the door unduly difficult to open under normal circumstances. Avoid over-tightening, as this can strain the closer mechanism. Regularly reassess the backcheck setting, as building usage or environmental conditions may change;

Troubleshooting Common Issues

Addressing frequent problems like latching failures or slamming doors often involves simple adjustments. Diagnosing the root cause ensures a lasting, effective solution for users.

Door Doesn’t Latch Properly

If your door fails to latch securely, the issue often stems from insufficient closing force or an improperly adjusted latching speed. Begin by verifying the door alignment; gaps can prevent the latch bolt from engaging the strike plate.

Next, slightly increase the closing speed (refer to the ‘Adjusting Closing Speed’ section) to provide more momentum. Simultaneously, focus on the latching speed – a faster latching speed can help overcome minor obstructions.

Inspect the strike plate for wear or misalignment. A worn strike plate may need replacement or adjustment. Ensure the latch bolt smoothly enters the strike plate without binding. If adjustments don’t resolve the issue, consider a professional inspection to rule out mechanical failures within the closer itself.

Door Slams Shut

A door slamming shut indicates excessive closing force, typically due to an overly fast closing speed or insufficient damping. Immediately address this to prevent damage to the door, frame, or closer mechanism.

Begin by significantly reducing the closing speed using the adjustment valve (see ‘Adjusting Closing Speed’). Make small adjustments and test the door’s movement after each change.

Simultaneously, increase the latching speed slightly; this can help absorb some of the final impact. If the door still slams, engage the backcheck feature (refer to ‘Backcheck Adjustment’) to control the door’s swing near the end of its travel. A properly adjusted backcheck will prevent forceful impacts. If problems persist, professional assistance is recommended.

Closer is Difficult to Open

If a door closer requires excessive force to initiate movement, it suggests either internal friction within the closer or an improperly adjusted closing speed combined with a strong latch. First, check for any visible obstructions or debris hindering the closer’s mechanism.

Attempt to slightly decrease the closing speed; a slower speed reduces the force needed to overcome the closer’s initial resistance. Ensure the latch isn’t binding or too tight, as this adds to the opening effort.

Consider lubricating the closer’s moving parts with a silicone-based lubricant (avoid oil-based products). If the issue remains, the closer may require professional servicing or replacement, indicating internal component wear or damage. Ignoring this can lead to further strain and potential failure.